High-speed space communication networks urgently require optical modules featuring high bandwidth,low latency,and miniaturization.In this paper,the displacement damage effect,single-event effect (SEE),and temperature characteristics of optical modules are investigated,aiming to elucidate the degradation patterns and underlying mechanisms of the key parameters of the optical modules in the space environment.Through the environmental tests,it is found that the incident neutrons introduce displacement damage defects in the vertical-cavity surface-emitting laser (VCSEL) and positive-intrinsic-negative (PIN) detector of the optical module,reducing the minority carrier lifetime and thus decreasing the optical output power and receiver sensitivity.The optical module is susceptible to the SEE.The heavy ions cause bit-flips in the registers within the driver circuits,resulting in communication bit-errors and communication interruptions.The threshold current of the VCSEL increases with temperature,which is the main reason for the degradation in the optical output power of the transmitter module.

To address the threats of radiation effects on the reliability in space environments,the radiation probabilistic risk assessment (PRA) methodologies for multi-core parallel fault-tolerant radiation-hardened computer systems (CCUs) are investigated.First,the single-event upset (SEU) rate distribution models for the critical memory devices,e.g.,programmable read only memory (PROM),magnetoresistive random access memory (MRAM),and static random access memory (SRAM),are developed based on the ground-based simulation test data.Three candidate empirical distributions,i.e.,exponential distribution,Weibull distribution,and log-normal distribution,are analyzed.The optimal fitting function is selected according to the maximum entropy principle,and it is shown that the SEU rates of the memory devices follow the log-normal distribution most reasonably.Second,a device failure probability model is established under the framework of the error detection and correction (EDAC) mechanisms.A system-level reliability modeling method is constructed for the CCUs,and the Monte Carlo simulation is adopted to derive the failure probability distribution over a 5-year mission lifecycle.Finally,the probability importance,structural importance,and relative importance of the components are analyzed,and the critical risk sources are quantified,by which the device hardening strategies and risk mitigation recommendations are suggested.The findings provide a theoretical foundation and quantitative support for the design of highly reliable radiation-tolerant systems.

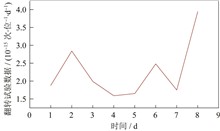

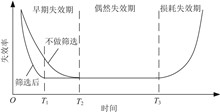

Highly reliable military microelectronic components are the cornerstone of quality in aerospace and defense weaponry.Design and manufacturing are the origins of reliability,while screening tests serve as a critical means to ensure it.Extensive screening,however,also increases the cost of component usage,making it urgently needed to carry out optimization research on screening tests oriented towards cost reduction.Currently,numerous studies have been conducted on the correlation between screening tests and manufacturing defects at home and abroad.The American Solid State Technology Association has even established the screening optimization standards for tailoring and optimizing later-stage screening tests by controlling the manufacturing defects.In this paper,the U.S.screening optimization standards are analyzed,and the manufacturing defects related to burn-in are examined.With the production testing data from 1 479 domestically produced 4-to-6-line decoders,the conditions required for optimizing burn-in test duration are determined.Additionally,the electrical parameters of both failed and normal devices under dynamic burn-in conditions are analyzed.The results reveal that,compared with the 240-h dynamic burn-in during the primary screening,the 40-h dynamic burn-in in the secondary screening induces a greater change in the input high-level current of the components.Furthermore,the 40-h dynamic burn-in in the secondary screening significantly reduces the static current,whereas the 240-h dynamic burn-in in the primary screening notably increases it.This indicates that the relationship between the burn-in duration and parameter drift is nonlinear,i.e.,longer burn-in time does not necessarily exert greater influence on the components.These findings demonstrate the feasibility of optimizing the duration of burn-in tests.

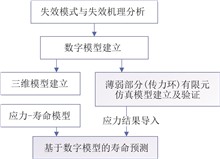

In response of the frequent failure problems of electromagnetic unlocking for aerospace separation electrical connectors,a reliability analysis method for the electromagnetic unlocking of separation electrical connectors is proposed based on digital models.A specific type of separation and release connector is selected as the research object.First,the functions,structure,and failure mechanisms of the connector are analyzed,by which the key failure modes are identified.Then,the digital models are used to simulate the unlocking process.A high-precision 3D model is established and combined with the finite element simulation analysis,by which the stresses exerted on the key components during the electromagnetic unlocking are analyzed.Finally,verification experiments are designed to validate the stress simulation results.Based on these results,the service life of the key components is predicted with the life prediction software.